injection moulding

Startseite > Know-How > injection moulding

Due to high qualifications, many years of experience and constant further training in the field of plastics technology, we are your competent partner.

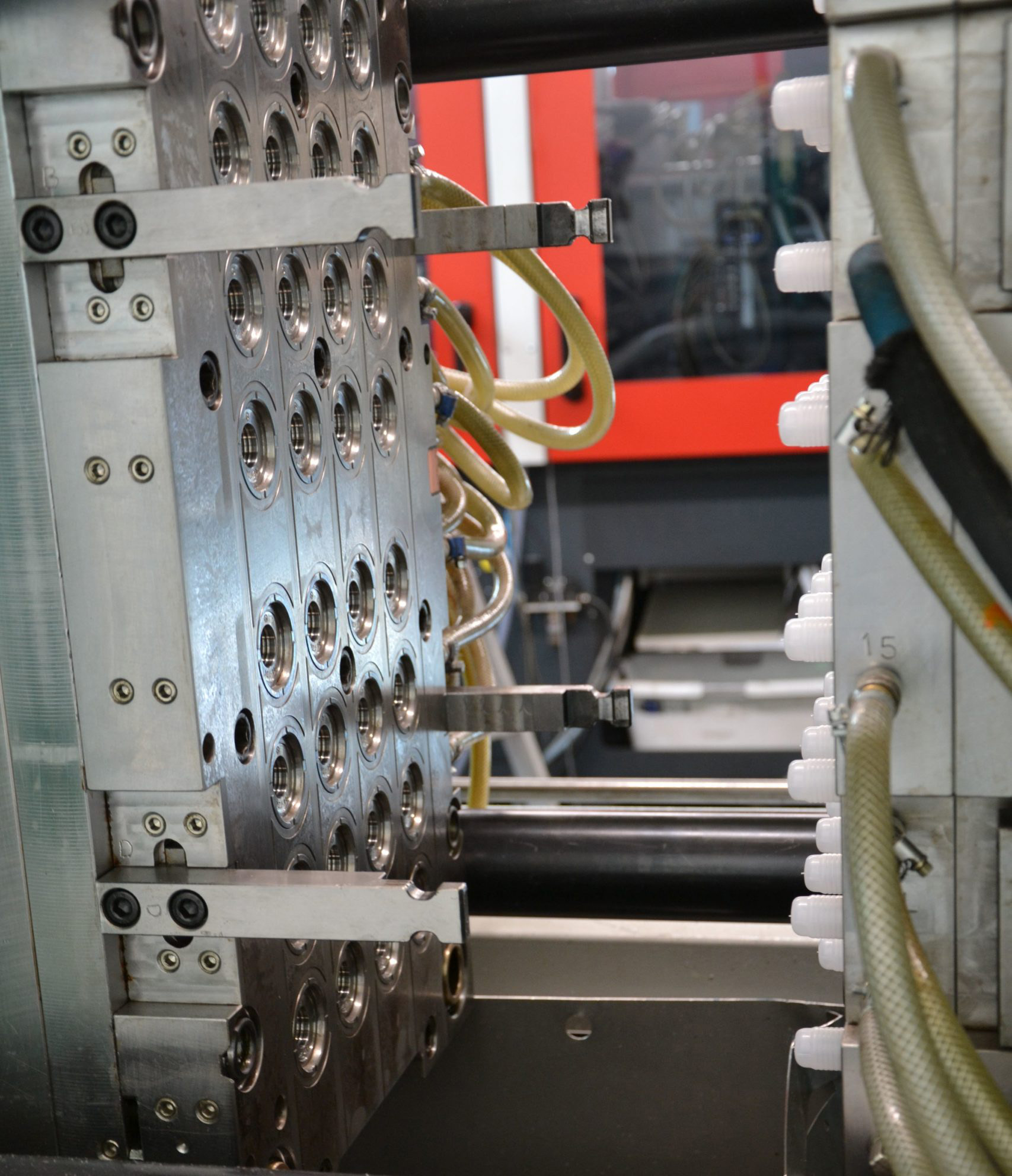

Our injection molding shop uses state-of-the-art, fully automatically controlled injection molding machines using the latest technologies. The machines enable us to respond more flexibly to customer requests and at the same time achieve a higher quality standard with reduced resource consumption.

We use two-component technology to achieve multicoloring and the processing of materials with different properties, for example to improve the feel using soft-touch surfaces or to save costs.

We process thermoplastics, whether virgin material or 100% recycled material, up to an injection weight of 1,000 g with a maximum holding force of 2,500 kN.

In close collaboration with our designers and our own tool shop, we produce high-quality injection molded parts.

Do you have any questions about our services or special requirements? Don't hesitate to contact us! We will be happy to advise you and find the optimal solution for your individual needs.

Pfefferkorn & Co GmbH

Reachable by telephone:

Mo – Do: 08:00 h – 16:00 h

Fr: 08:00 h – 13:00 h