tool making

Startseite > Know-How > tool making

High-tech in precision

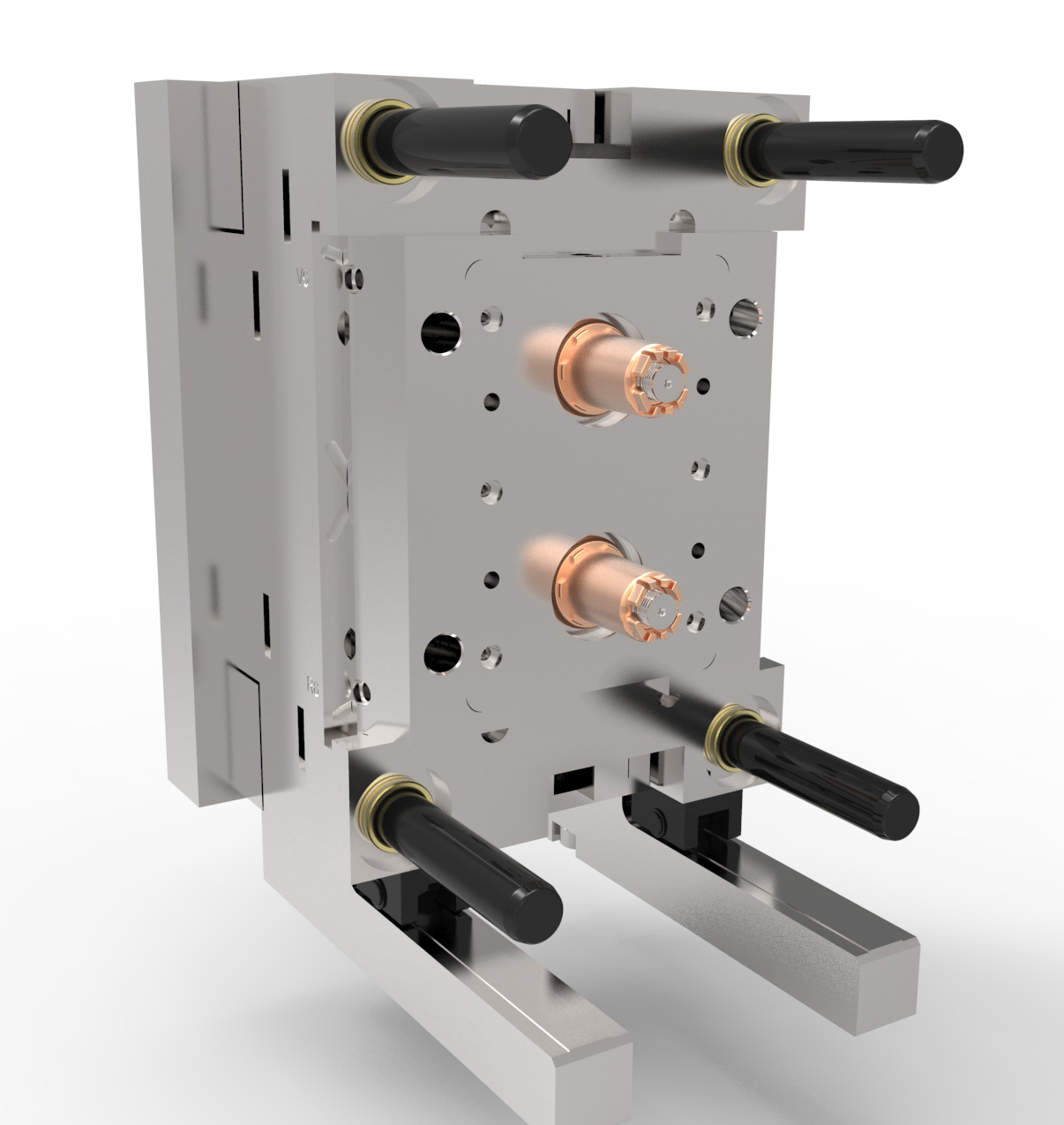

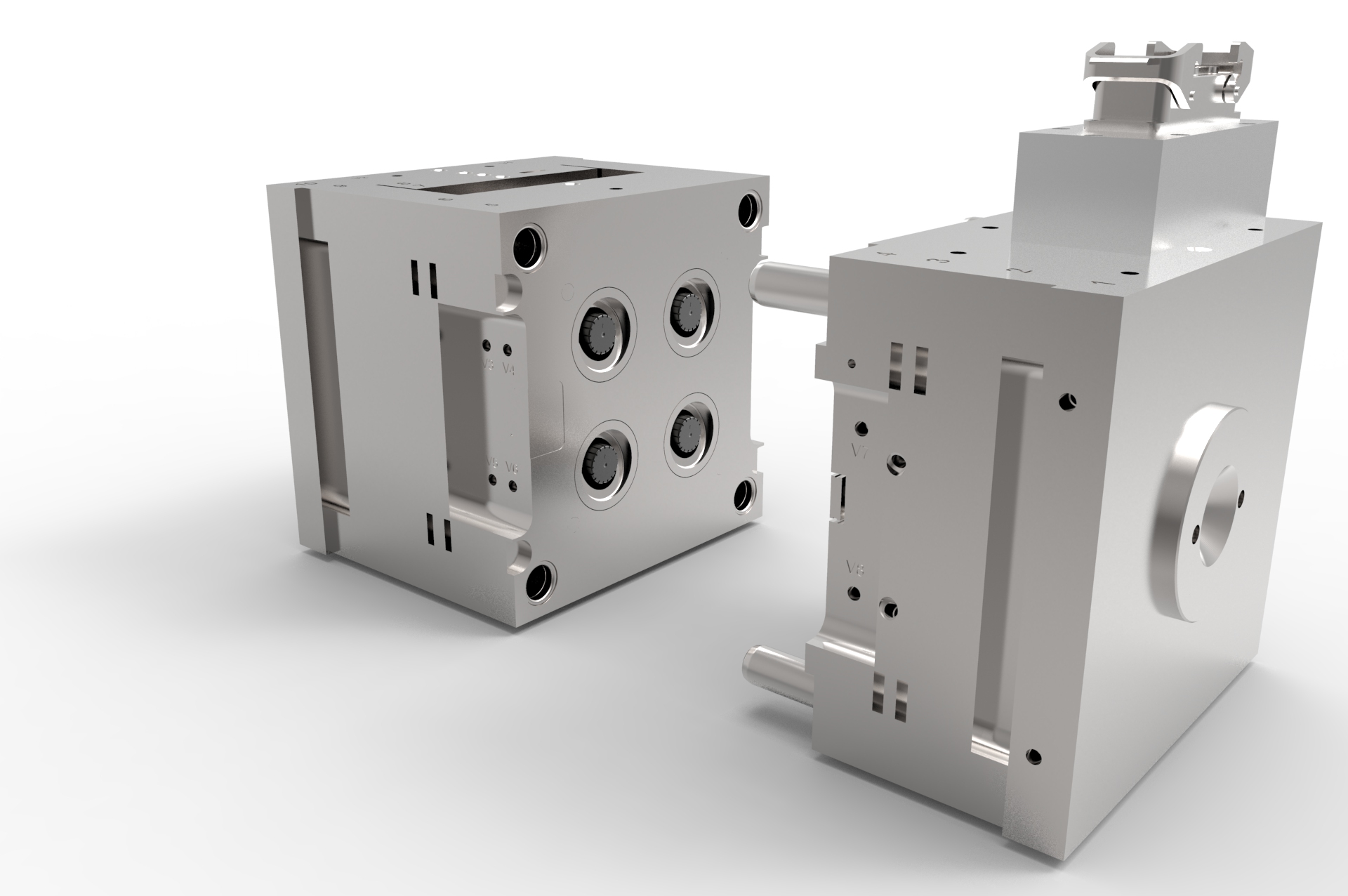

Our tool shop produces injection molding tools of the highest precision using state-of-the-art, computer-controlled processing machines.

In single-shift operation with flexible working hours, we create injection molds for customers as well as for our own injection molding area.

We also maintain, repair and maintain our customers’ tools.

Finest engravings and details

Our know-how ranges from simple 2-plate tools to complex demolding concepts with turning, collapsing or hydraulic cores to complex 2-component tools and hot runner tools with needle gate systems, for example for material- and cost-saving multi-cavity tools. We create molds for injection molded parts with inserts as well as interchangeable inserts or plates with a precise fit. The finest engravings and delicate details are eroded into the tools using electrodes.

As part of our quality assurance, we measure both our plastic parts and our tools on 3D coordinate measuring machines.

We also offer these measurements and the creation of measurement protocols as a service.

Do you have any questions about our services or special requirements? Don't hesitate to contact us! We will be happy to advise you and find the optimal solution for your individual needs.

Pfefferkorn & Co GmbH

Reachable by telephone:

Mo – Do: 08:00 h – 16:00 h

Fr: 08:00 h – 13:00 h